Protection Pads

Equipment, Door, and Elevator Protection

Building owners with expensive doors or elevators installed to improve the aesthetics and security of their buildings often run into a common and unavoidable problem: dings and scrapes from hand trucks, delivery workers, contractors, or maintenance teams. These visual and sometimes even structural disruptions in the doors and elevators are often difficult or impossible to remove, leaving the owners with the option of ignoring the issue or just replacing the door/elevator altogether which, as you can probably guess, costs a pretty penny.

A former coworker and I found that building owners are willing to pay for a semi-permanent solution that preserves the integrity and aesthetics of their doors, elevators, and equipment by taking the brunt of the abuse. Our Protection Pads aim to do just that.

We are currently working with local commercial building owners to deliver a solution that prevents damage at a reasonable price point. We have several prototypes actively being used at local businesses for the purpose of product testing and are working towards a final design that meets our customers’ durability and aesthetic requirements.

Some of our first prototypes (early in product development)

Current Design

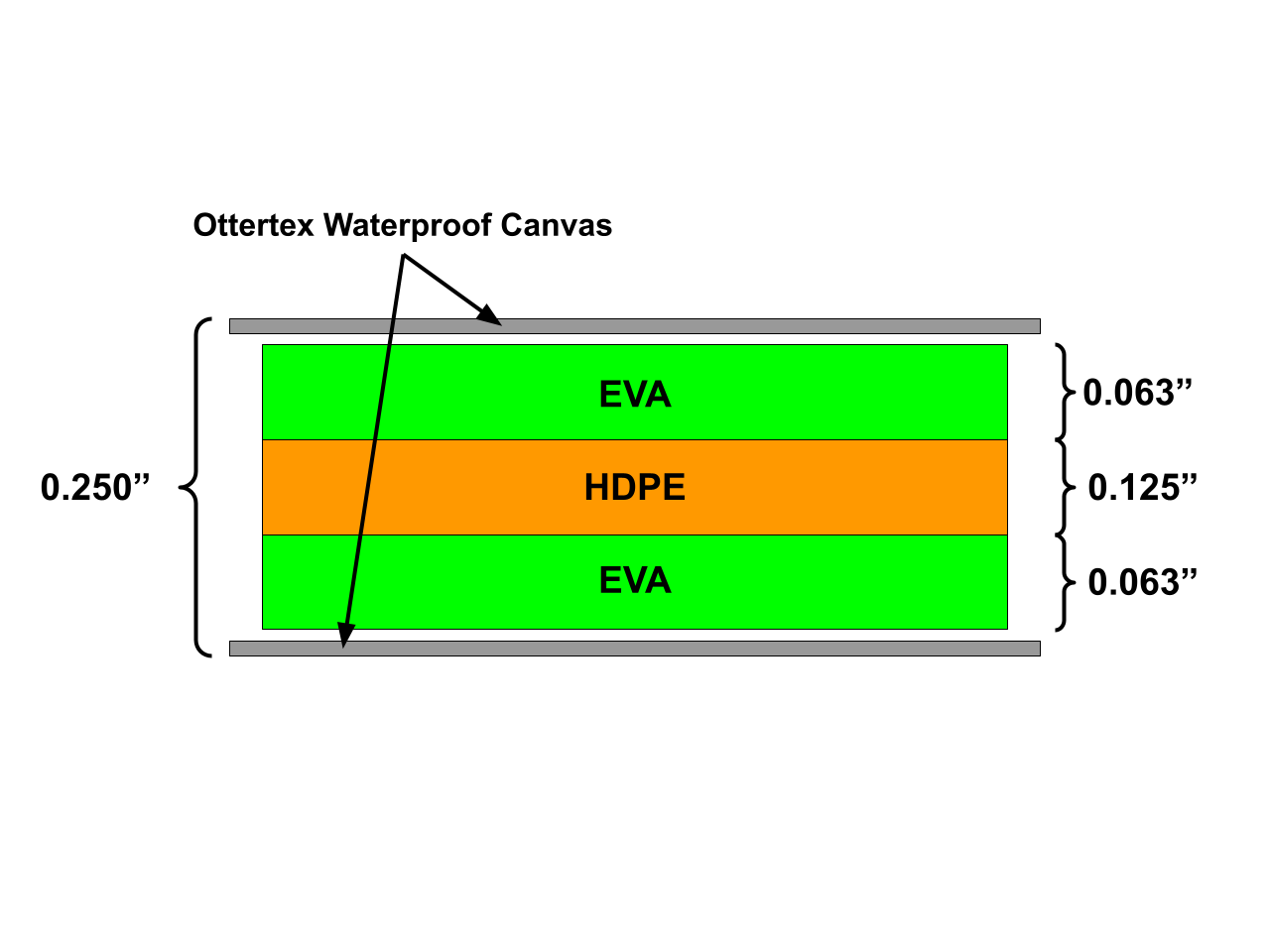

We have now been through a few rounds of product testing on a small scale and have used various combinations of materials to balance durability, aesthetics, and shock absorbance. We’ve found that using a combination of Ethylene Vinyl-Acetate (EVA) foam and High-Density Polyethylene (HDPE) board with a waterproof canvas shell best meets our customers’ requirements. We are currently ONLY working on models to fit doors in order to prove the effectiveness of the product. Designs for other applications to follow.

Design Breakdown:

Ethylene Vinyl-Acetate: EVA is a cheap, lightweight, foam-able plastic that provides the outer cushioning layers of the Pads’ interior and serves as the Pads’ “impact mitigator”. EVA foam is great at absorbing large impacts over a wide area (hand trucks, carts, etc.) and provides a protective boundary that disperses forces that may otherwise damage the inner HDPE layer from the impact-facing side. On the door-facing side, the EVA also smooths more concentrated impacts that have already been dispersed by the HDPE layer.

High-Density Polyethylene: HDPE is a lightweight, durable, stiff material commonly used in riot armor for police and police horses for protection against (non-firearm) projectiles. It’s used similarly in our product for dispersing concentrated impacts over a larger area to prevent denting caused by sharper objects (snowblowers, tools, etc.).

Ottertex Waterproof Canvas: Waterproof canvas gives our product a durable, weatherproof shell that’s resistant to ripping, tearing, and cutting. This protects the inner layers and gives the product a tough, non-visually-disrupting look that can be used in the summer or winter, rain or shine.

Attachment: The pads need to attach to the doors somehow and we needed to find a solution that could handle the abuse while also allowing for quick and easy installation and removal. Since we need to avoid causing scratches or marks on the doors, we went with a plastic quick-release buckle, a lightweight, cost-efficient component that’s strong where we need it to be and meets all design requirements. Though we are exploring other securing methods, we’ve had no problems with the quick-release buckle so far.

Other Design Considerations:

Pad Size: The pads are currently 14”H x 34”W so that they fit within common door widths. While we’ve considered taller pads, the majority of building owners that we’ve spoken to are most concerned with the very bottoms of their doors as that area receives the most impact so it’s not worth the extra material (we’d have to purchase larger HDPE sheets). If a building owner really needs more space covered, multiple mats can be used in tandem to provide a larger protected area.